Zenmov Intelligence

You can use it on various devices such as computers, tablets, and smartphones.

It is difficult to respond to absences or changes/additions to destinations on the day.

I want to regularly review the delivery and patrol routes to reduce costs, but,

I don't even know what the correct answer is...

It takes time to plan.

Because it is an old-fashioned analog planning method by a skilled dispatcher,

it takes time, and sometimes mistakes happen...

Business personalization

There are instincts and information that only specific employees possess, along with unique know-how, and there is variability in skills.

It has become a response to sudden vacancies and a barrier to business expansion.

You can specify morning/afternoon and specific times for each destination.

You can also specify the driver's working/break times and the vehicle's loading capacity.

Resource Planner

Operation Video

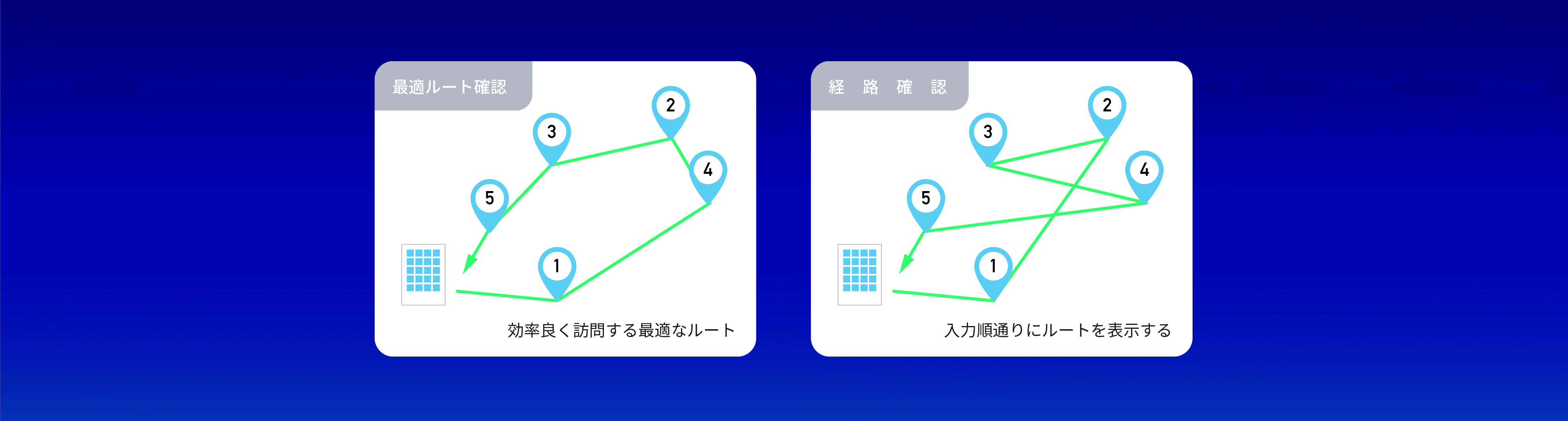

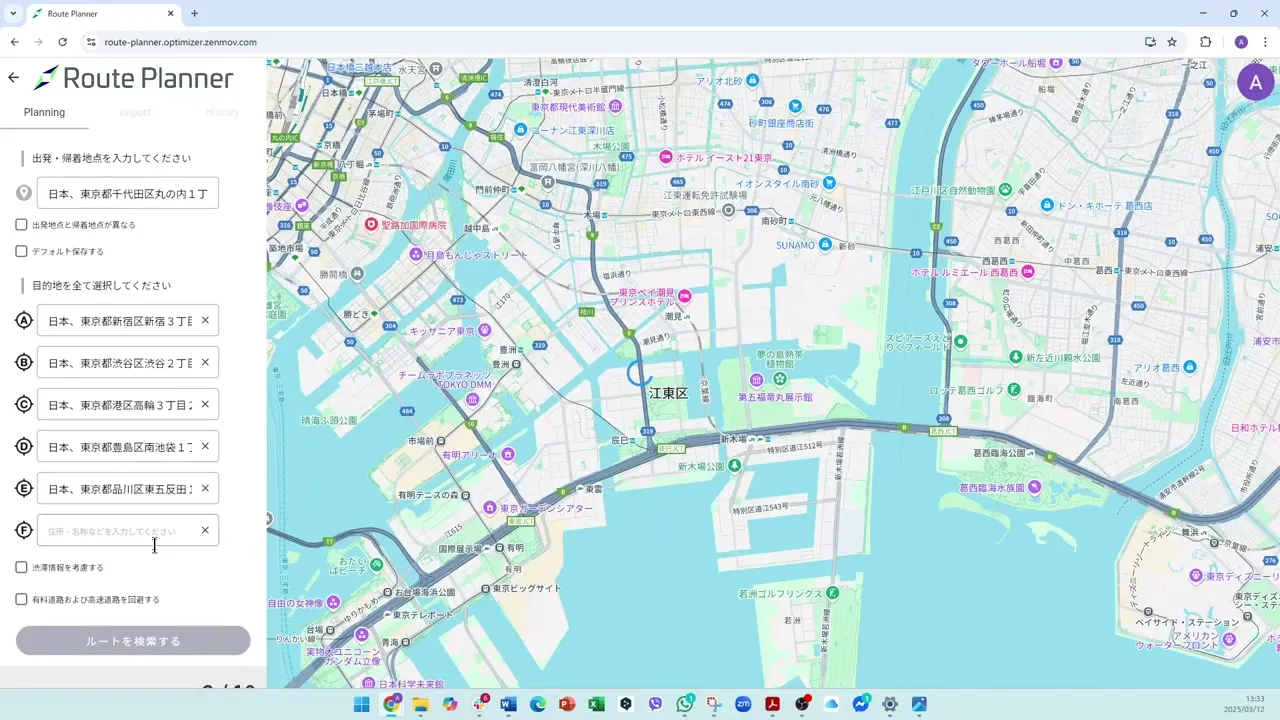

Route Planner

You can leave all the arrangements for the order, route plan for visits, rounds, and deliveries to us.

Operation Video

Delivery business (home delivery / EC last mile)

Every morning, planning vehicle dispatch and loading takes time and tends to become personalized. At the same time, there are frequent additional requests and rescheduling based on time, so there is a need for this.

The skills of each engineer and the inventory of automotive parts vary, making it difficult to rearrange the order of visits. When emergency repairs come in, existing schedules are disrupted, leading to a demand for automation.

Based on each customer's emission cycle data, we will pre-arrange the optimal collection schedule, but during busy periods (such as after holidays or at the end of the fiscal year), we may increase special rounds.

Additionally, since the customer also has to prepare for the collection and be present, strict adherence to time is required, making planning utilizing AI effective.

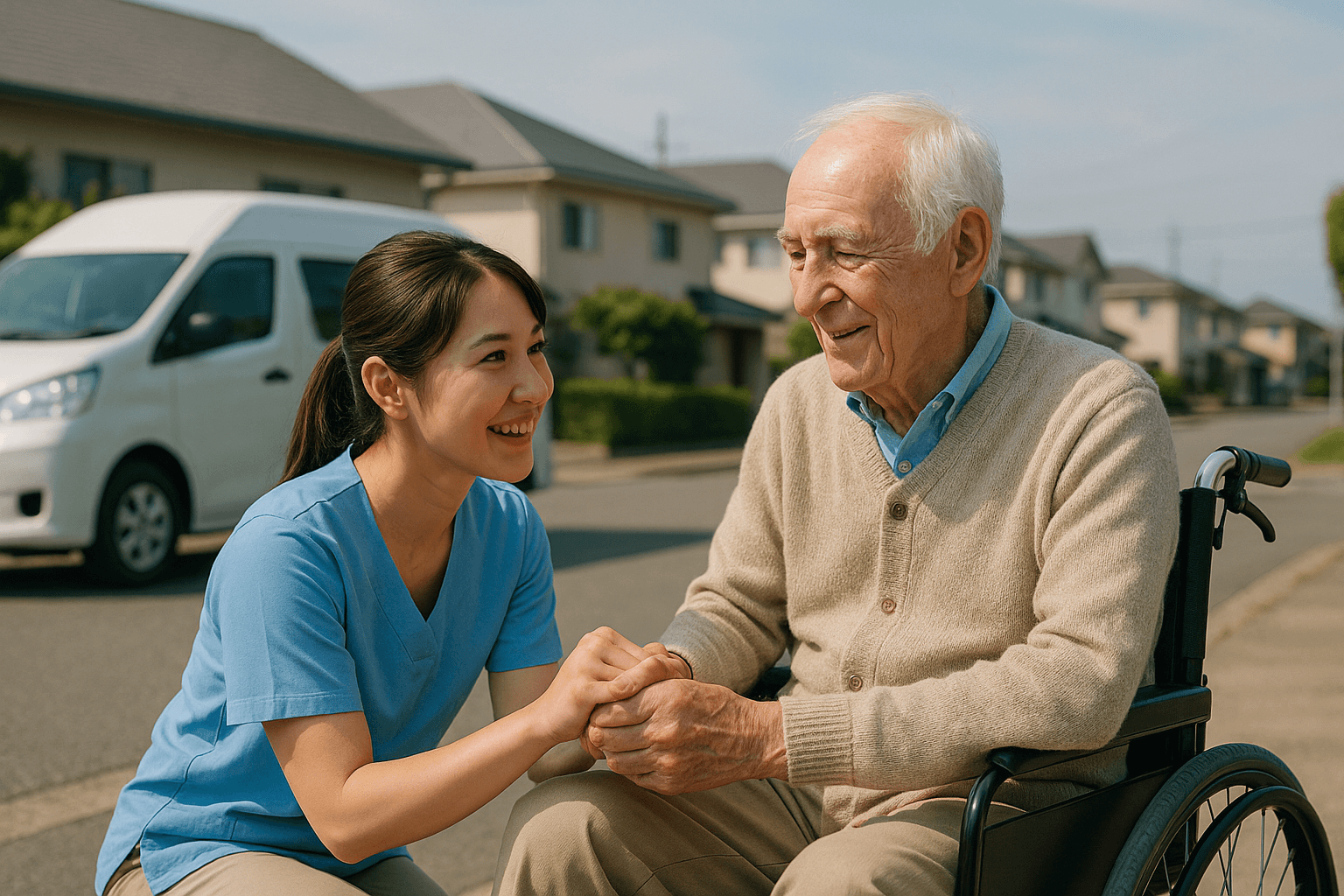

Nursing and care industry

Due to the differences in fixed time slots and care content for each user, along with frequent unexpected changes and cancellations, manual rearrangement becomes a burden.

Furthermore, consideration for the caregivers' breaks and travel burdens is necessary, and the number of inquiries has been increasing.

We have also been adopted by companies with a 75% market share in the automotive parts distribution system.

We reduced the time for order combination from multiple repair/maintenance providers and scheduling of delivery vehicles by 50%.

We also carry out individual customizations and have received high praise for our user-friendliness.

Flow of use

Sample data for experience can be downloaded from the app screen.

You can easily import data into the application using drag and drop.

You can set the load capacity and driver working hours as needed.

Simply click the optimization start button to complete the calculation.

Please check the calculation results.